China High Quality High Efficiency Worm Gear Series Double Enveloping Worm Gear Unit Worm Gearbox Air Compressor CHINAMFG Freight

Product Description

The High Efficiency Cone Worm Gear Series Double Enveloping Worm Gear Unit Worm Gearbox is a high-quality gear unit designed for tough working conditions. It offers a range of features and benefits, including:

- Universal design for various applications

- Smooth and noiseless operation

- Higher driving efficiency compared to traditional worm gears

- Increased loading capacity

- Strict quality testing before shipping

- Customized design options

- Long service life

- Suitable price with moderate pricing

- High quality

In a Worm Gearbox, Worm Reduction Gear Box, Worm Speed Reducer, and Gear Motor Manufacturer, multiple gear teeth are in contact with the worm, increasing torque capacity and shock load resistance. The double-enveloping worm gearing configuration allows for increased power transmission capability and reduced stress on each gear tooth.

Working Conditions

The double enveloping worm gear reducer is designed for two shafts that intersect at 90°. The input speed should not exceed 1500 rpm, and the working environment temperature should range from 0°C to 40°C. Before starting, the lubricating oil should be heated or cooled accordingly. The worm shafts support both forward and reverse operation.

Data Sheet on CUW Double Enveloping Worm Gear Reducer:

| Model | Shaft Dia. (mm) | Center Height (CUW) | (CUW) Output Shaft Dia. | Power | Ratio | Permitted Torque | Weight |

| (CUW) input Solid(h6) | (mm) | (mm) | (kW) | (Nm) | (KGS) | ||

| 100 | 28 | 190 | 48 | 1.41~11.5 | 10.25~62 | 683-1094 | 42 |

Advantage

The CHINAMFG High Efficiency, Low Noise Cone Worm Series Worm Gearbox design offers several advantages. First, the load is divided among more individual gear teeth, increasing load carrying capacity. Second, the improved torque throughput allows for size and weight savings. The double-enveloping worm gearing can handle loads that would require much larger and heavier cylindrical worm gearing.

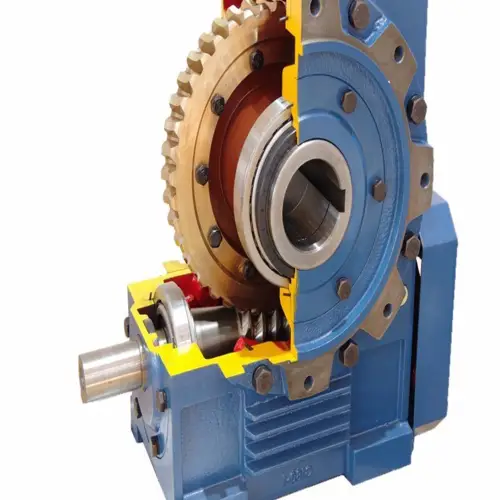

Double-Enveloping Worm Gearbox Figure:

(Click on picture for more information)

Packaging & Shipping

Package: SGR gearbox uses standard wood case per gear motor/gear unit.

Shipping: We deliver products according to customer requirements, using various modes of transport such as sea shipping, air transportation/express, or truck transportation.

You Appoint, We Service!

Our Services

With all our activities DNV-ISO 9001 and SGS-certified, we stand for top-quality service. Our gearbox products are designed to protect against wear and grinding, ensuring reliable and efficient torque conversion. We offer customization options for various gear units, including planetary gear units, helical gear motors, modular design helical gear units, worm gearboxes, cycloidal gearboxes, and more. Our gear units have a service life of over 200,000 operational hours and are trusted by customers worldwide.

Frequently Asked Questions (FAQs)

- What are the advantages of the High Efficiency Cone Worm Gear Series Double Enveloping Worm Gear Unit Worm Gearbox?

- What working conditions is the double enveloping worm gear reducer designed for?

- How does the configuration of double-enveloping worm gearing improve power transmission capability?

- How is the load carrying capacity increased in the double-enveloping worm gear design?

- What packaging and shipping options are available for the gear units?

For more information and inquiries about our industrial products, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more, please feel free to contact us. We offer high-quality products, competitive prices, and customized solutions to meet your specific requirements.

All the content of this page is from the Internet and is only intended as a reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier for purchase.

Performance Characteristics of Worm Gearbox

Worm gearbox offers several performance characteristics that make it an ideal choice for various applications:

- High Efficiency: The worm gearbox provides high efficiency, ensuring maximum power transmission.

- Compact Design: Its compact design allows for easy installation and integration into different systems.

- High Torque: The worm gearbox offers high torque output, making it suitable for heavy-duty applications.

- Smooth Operation: It provides smooth and quiet operation, minimizing noise and vibration.

- Reliable and Durable: Worm gearbox is known for its reliability and durability, ensuring long-lasting performance.

- Self-Locking: The self-locking feature of the worm gearbox prevents it from back-driving, providing enhanced safety and stability.

Types and Characteristics of Worm Gearbox

Worm gearboxes are available in various types, each offering unique characteristics:

- Non-Reversible Worm Gearbox: This type of worm gearbox is designed for one-directional power transmission, suitable for applications where back-driving is not required.

- Reversible Worm Gearbox: Reversible worm gearbox allows for bidirectional power transmission, making it suitable for applications that require back-driving.

- Right-Angle Worm Gearbox: The right-angle worm gearbox is designed to transmit power at a 90-degree angle, allowing for compact and space-saving installations.

Advantages of Worm Gearbox Made of Different Materials

Worm gearboxes can be made of various materials, each offering its own advantages:

- Cast Iron Worm Gearbox: Cast iron worm gearbox provides excellent strength and durability, making it suitable for heavy-duty applications.

- Aluminum Worm Gearbox: Aluminum worm gearbox is lightweight and corrosion-resistant, ideal for applications where weight and environmental factors are a concern.

- Stainless Steel Worm Gearbox: Stainless steel worm gearbox offers superior resistance to corrosion and high temperatures, making it suitable for demanding environments.

Application of Worm Gearbox in Various Fields

Worm gearbox finds its value and importance in various fields, including:

- Material Handling: Worm gearbox is widely used in material handling equipment, providing efficient power transmission for conveyor systems and lifting mechanisms.

- Packaging Machinery: Worm gearbox plays a crucial role in packaging machinery, ensuring precise and reliable movement of packaging components.

- Food Processing: The hygienic design and smooth operation of worm gearbox make it suitable for food processing equipment where cleanliness and efficiency are essential.

- Textile Industry: Worm gearbox is utilized in textile machinery for precise control and synchronized movement of various components.

Future Development Trends and Opportunities of Worm Gearbox Products

The future of worm gearbox products holds several development trends and opportunities:

- Advanced Materials: The use of advanced materials in worm gearbox construction will enhance performance and durability.

- Improved Efficiency: Continuous advancements in gear technology will lead to enhanced efficiency and power transmission capabilities.

- Smart and Connected Gearboxes: Integration of smart and connected technologies will enable remote monitoring and predictive maintenance of worm gearboxes.

- Automation and Industry 4.0: The increasing adoption of automation and Industry 4.0 principles will drive the demand for efficient and reliable worm gearbox solutions.

Choosing a Suitable Worm Gearbox

When selecting a suitable worm gearbox, several aspects should be considered:

- Load Requirements: Determine the torque and power requirements of your application to ensure the selected worm gearbox can handle the load.

- Ratio Selection: Choose the appropriate gear ratio to achieve the desired speed and torque output.

- Type of Gearbox: Consider the specific type of worm gearbox that best suits your application’s needs, such as non-reversible, reversible, or right-angle.

- Environmental Factors: Evaluate the environmental conditions, including temperature, humidity, and the presence of corrosive substances, to select a gearbox with suitable material and protection features.

- Maintenance and Durability: Assess the maintenance requirements and expected lifespan of the worm gearbox to ensure it meets your long-term operational needs.

In conclusion, worm gearbox offers excellent performance characteristics, various types, and advantages based on different materials. Its application in different industries demonstrates its value and importance. The future holds promising trends and opportunities for worm gearbox products, driven by advancements in materials, efficiency, smart technologies, and automation. When choosing a suitable worm gearbox, considering load requirements, ratio selection, gearbox type, environmental factors, maintenance, and durability is crucial for optimal performance.

Author: Dream